AUXILIARY ASSEMBLIES

EXTENDING PACKAGING CAPABILITIES

In order to assist and upgrade the packaging procedure, Sinpack Engineering has carefully engineered further technical assemblies that are necessary to every packaging process. This accessory equipment can vary from simple conveying mechanisms such as belt conveyors and screw conveyors to more complex mechanical compositions that can provide extensive capabilities to the whole packaging process.

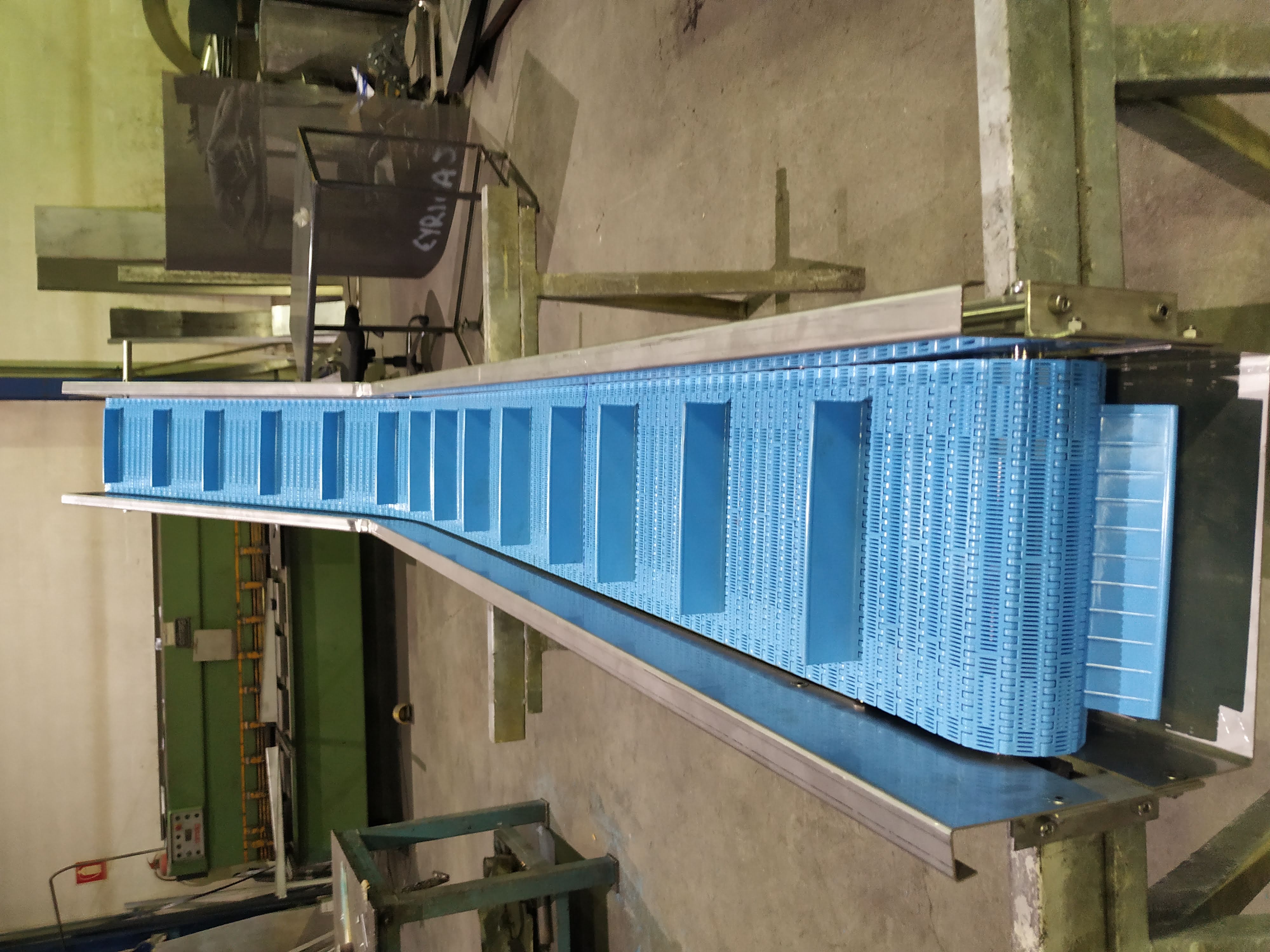

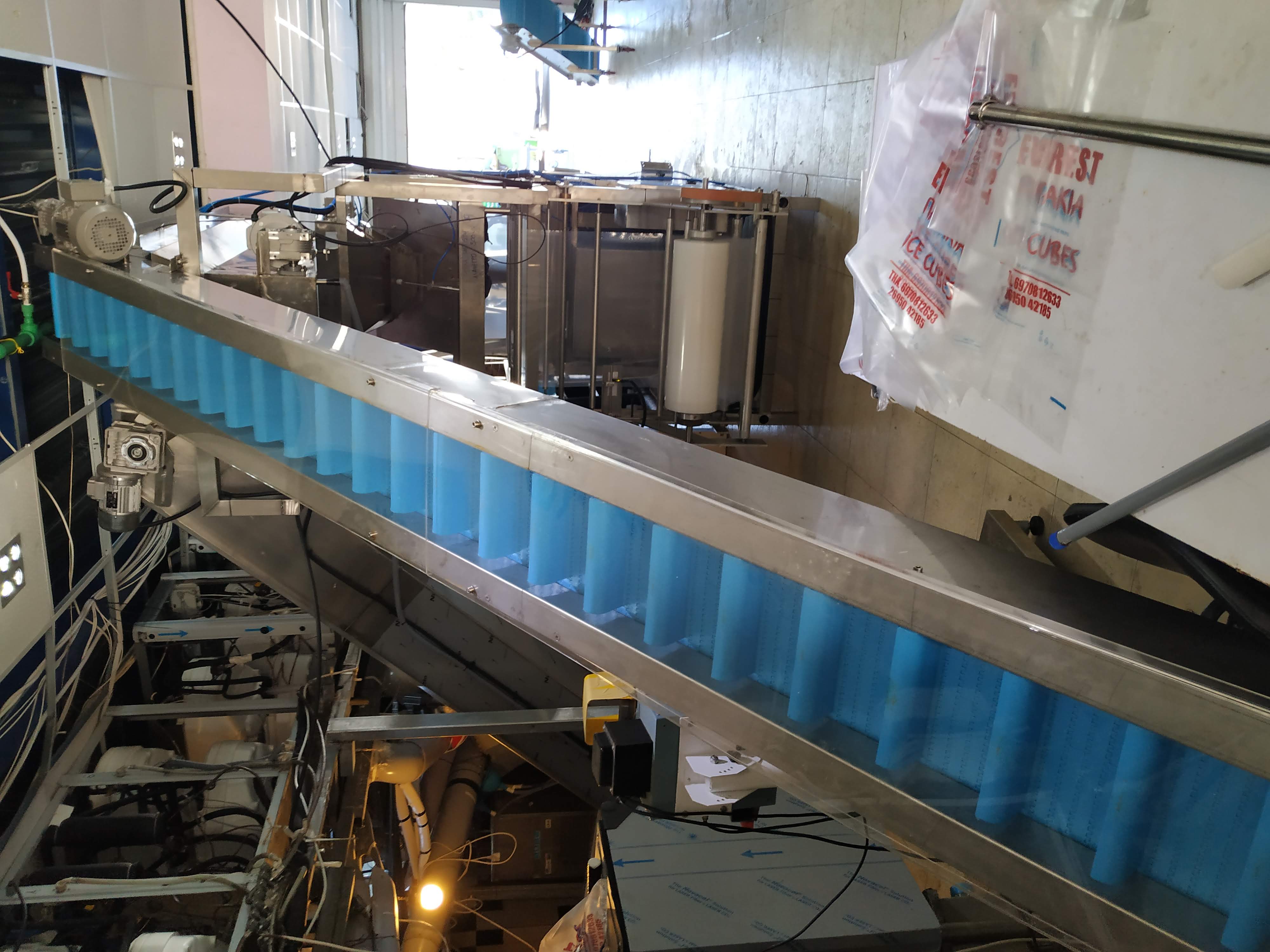

Almost in every project there was a high demand of feeding mechanisms in several different segments of a packaging process. Specially customized conveying systems have been developed that are appropriately matched and integrated upon client request.

Going one step further in the field of ice packaging, Sinpack Engineering was the first company to offer supplementary functionalities to the packaging system such as the removal of unnecessary ice fragments that should not be included in the final packaging process.

Discover what you can benefit from our advanced engineering methods

“VARELAKI” assembly is placed before the feeding system (inclined elevator) of the packaging machine and rejects all these small ice elements. The result is that the final ice bags created by the automatic packaging machine are fed with solid ice cubes.

- MECHANISM

- Length x Width

- Conveying method

- Rotary speed

- Power

- MECHANISM

- Length x Width

- Conveying method

- Rotary speed

- Power

- MECHANISM

- Length x Width

- Conveying method

- Rotary speed

- Power

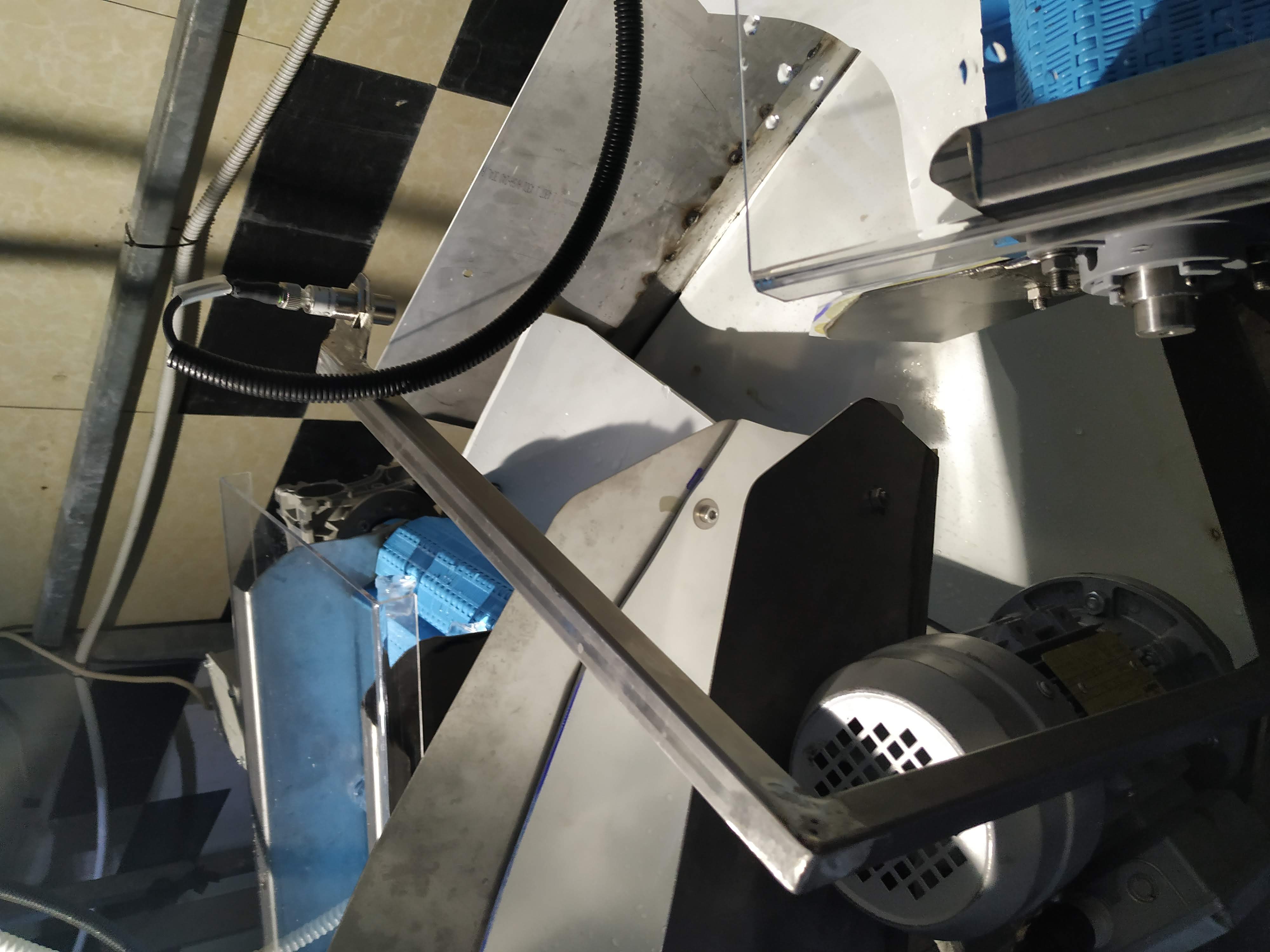

- Trim Filter "VARELAKI"

- 2000mm x 800mm

- Centrifugal force

- Approximately 20RPM

- 0.5HP

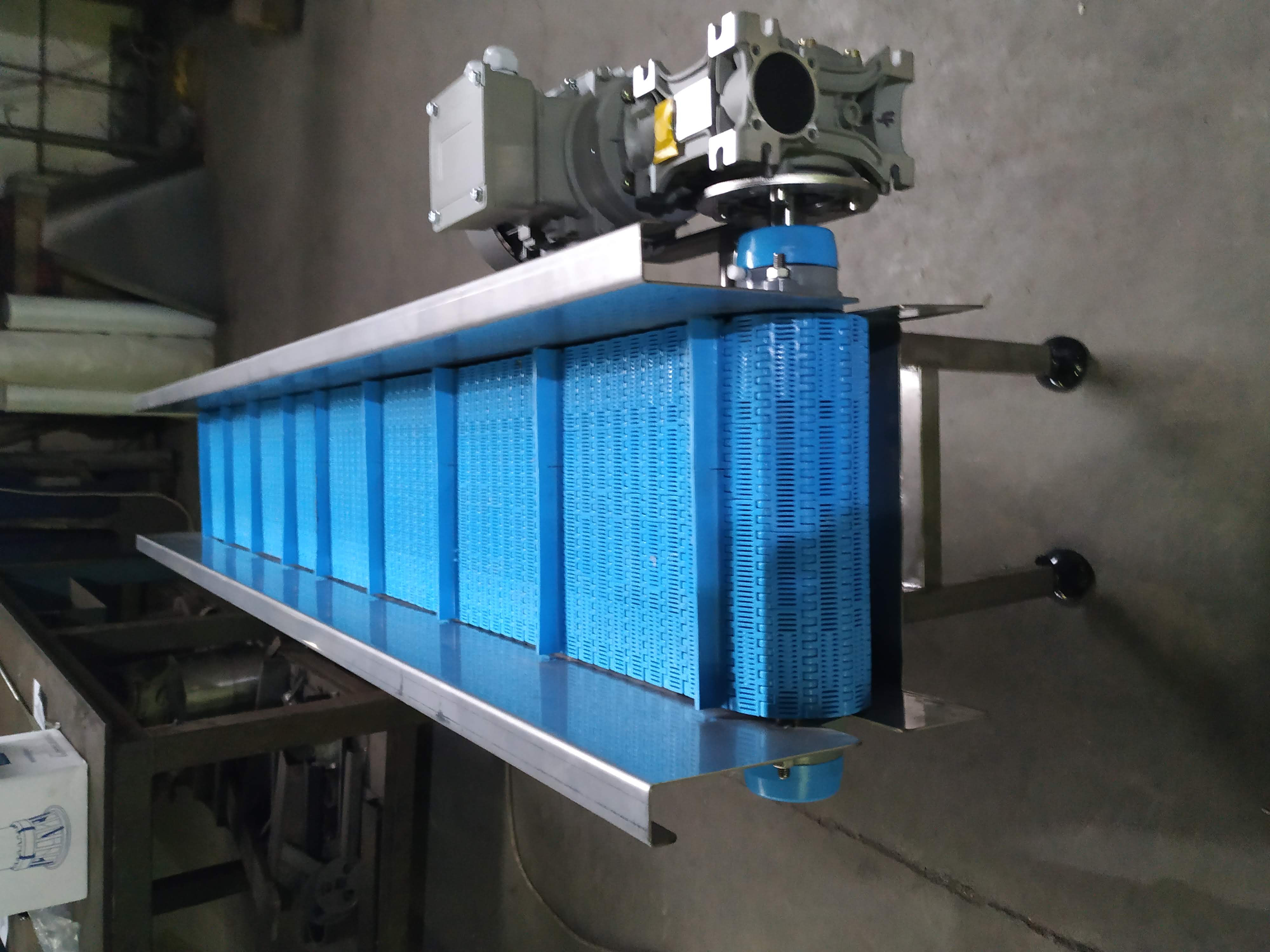

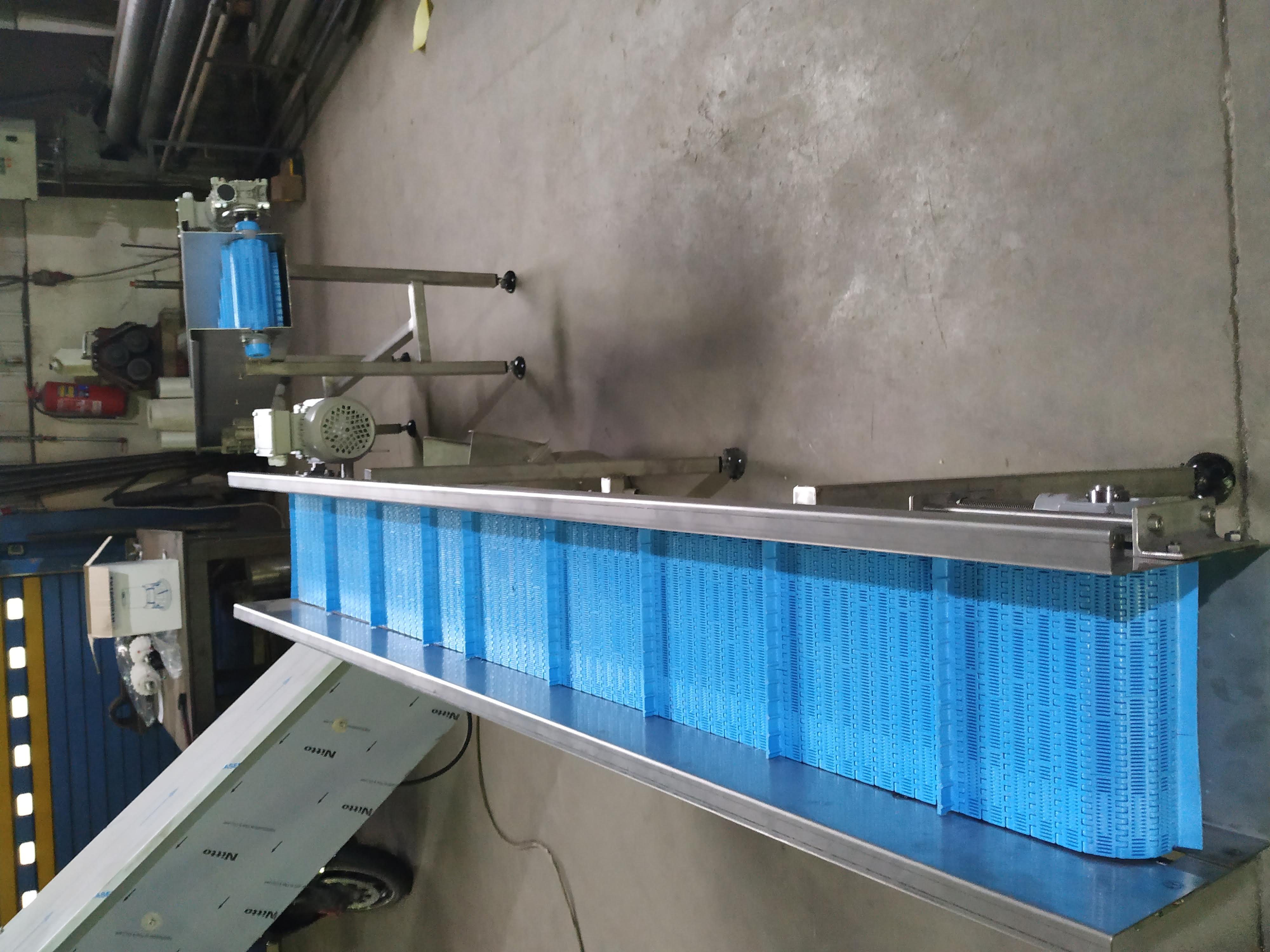

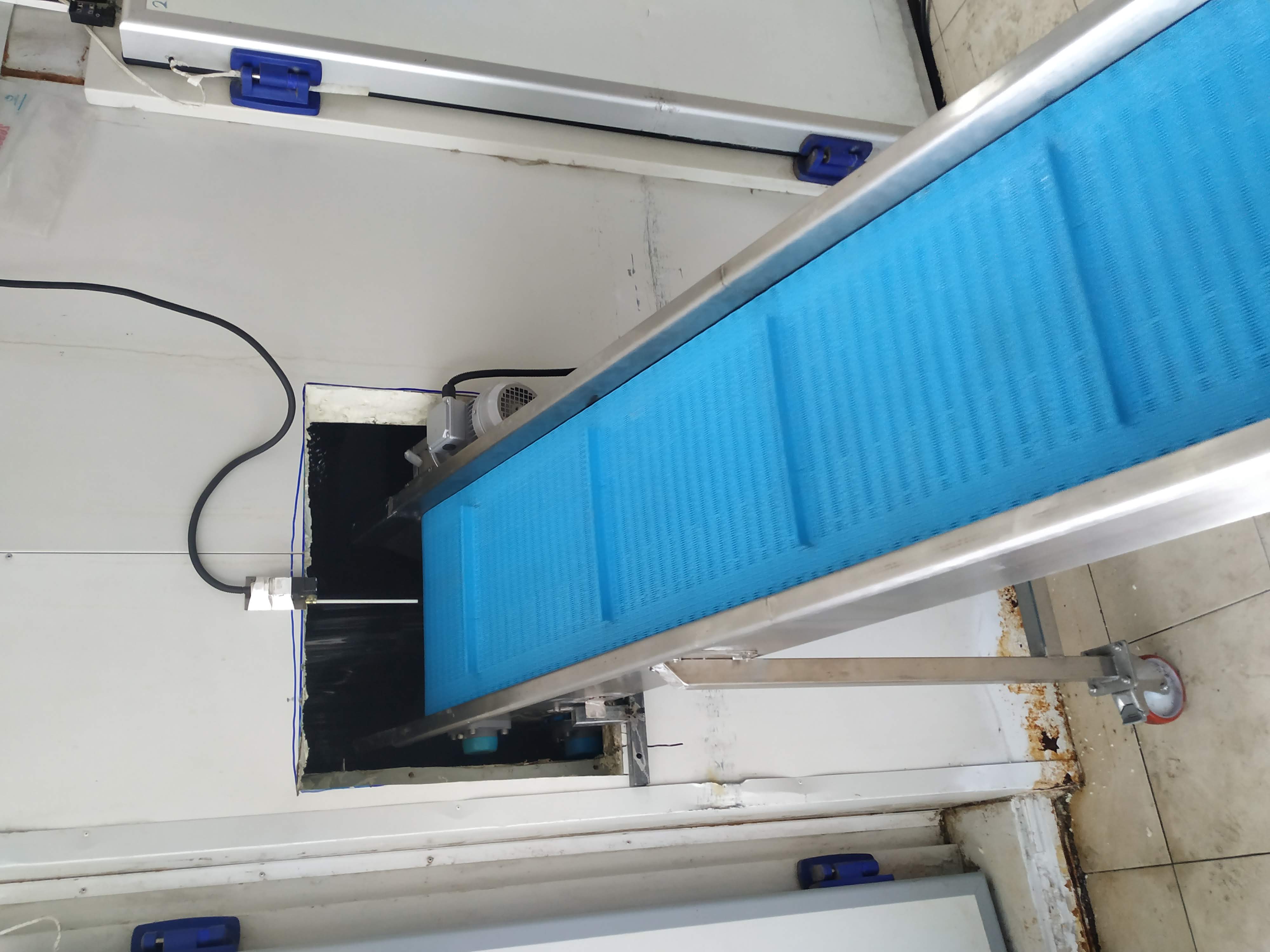

- Belt Conveyor

- Custom dimensions

- Tension on plastic belt

- Approximately 20RPM

- 1 -> 3 HP

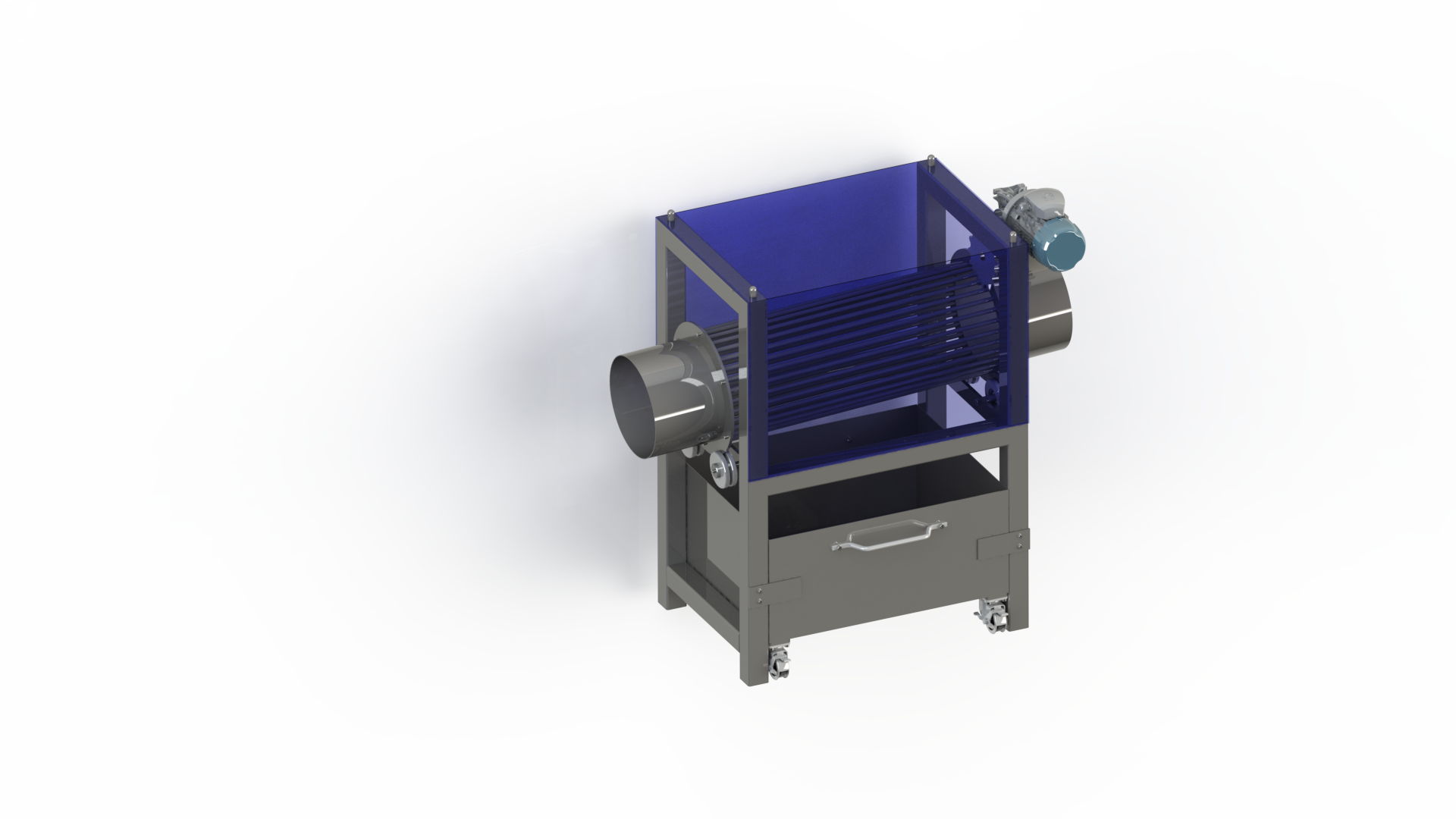

- Screw Conveyor

- Custom dimensions

- Centrifugal force

- Approximately 20RPM

- 1 -> 4 HP