ICE STORAGE & TRANSFER

Especially designed to facilitate the transfer of ice cubes

After the initial breakthrough during 2010 with the first ice packaging machine, Sinpack Engineering decided to evolve ice packaging and provide fully integrated solutions that include every stage of ice packaging from the time ice cubes are created until the time they packaged.

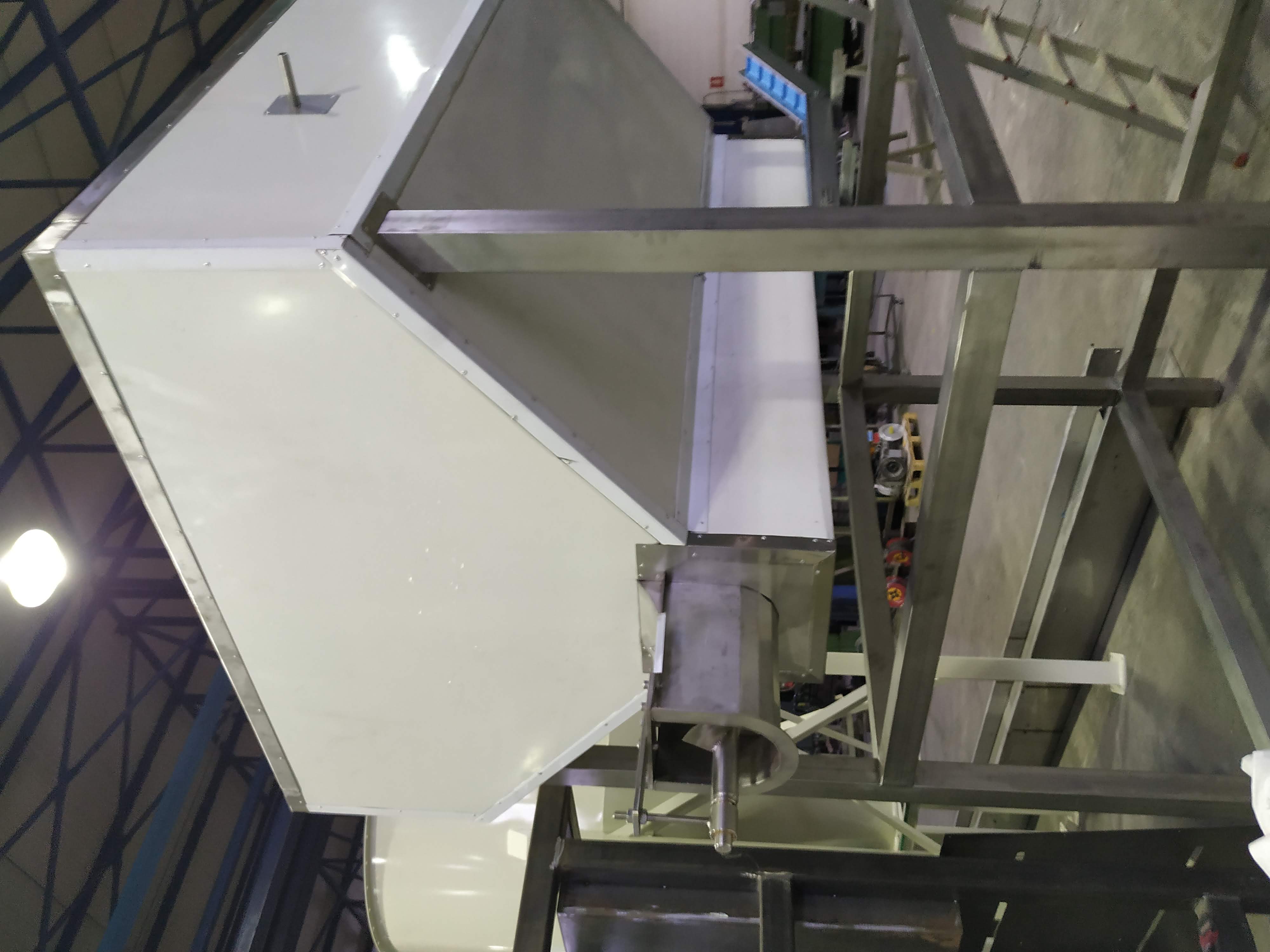

Therefore, along with the packaging assembly, after careful engineering research, a specific type of insulated containers has been developed in order to facilitate the accumulation of ice cubes. The concentrated ice cubes would be afterwards transferred through a screw-conveying system installed at the bottom of the container to the other segments of the ice packaging cycle.

Discover what ice container is best for you

Specially designed and manufactured stainless steel assembly responsible for the collection, storage and transfer of ice cubes in order to feed the VARELAKI assembly and subsequently the automatic packaging machine. The assembly is designed as to be able to withstand on the top of its structure, a specific number of machines that produce ice cubes. The models of the ice cubes machines may vary in origin of company and in dimensions.

Once the ice cube machines are placed accurately on the top of the tank, they generate batches of ice cubes directed at the interior of the tank. The bottom of the tank is equipped with a specially designed screw conveyor made of 304L stainless steel, that guides the ice cubes to the insert point of the VARELAKI assembly.

- Height

- Width

- Length

- Insulation

- Feeding system

- 1800mm -> 2100mm

- 1800mm -> 2400mm

- 3000mm -> 7.500mm

- Polyurethane 100mm thickness

- Screw conveyor 3 -> 5HP